Cutting-edge DTF Printing Solutions: Improve Your Garments with Direct-to-Film Technology

Cutting-edge DTF Printing Solutions: Improve Your Garments with Direct-to-Film Technology

Blog Article

From Idea to Development: Releasing Imagination With DTF Printing on Various Fabrics

In today's dynamic realm of fabric design, the application of Straight to Film (DTF) printing modern technology has revolutionized the procedure of transferring intricate styles onto various textiles. The fusion of innovation and creativity through DTF printing opens up doors to a realm where creative imagination knows no bounds.

Exploring the Benefits of DTF Printing

One crucial benefit of DTF printing is its convenience in terms of the fabrics it can be applied to. Unlike some conventional techniques that are restricted to certain textile types, DTF printing can be used on a wide variety of materials, including cotton, polyester, blends, and even leather.

Furthermore, DTF printing uses exceptional sturdiness, making it suitable for generating long-lasting designs on fabrics - DTF Printing. The prints produced via DTF are recognized for their vibrant colors and resistance to fading, cracking, or peeling - guaranteeing that the last item maintains its quality even after several cleans or extended use. This sturdiness makes DTF printing an affordable service for producers looking to create high-grade, long-term layouts on fabrics

Designing With DTF: Tips and Tricks

Creating properly with DTF printing entails grasping the intricacies of electronic style software application and comprehending exactly how to enhance styles for the very best outcomes on different fabrics. When creating styles for DTF printing, it is important to consider the textile shade, texture, and kind to make sure that the final product meets assumptions. Below are some techniques and pointers to improve your DTF layout process:

Resolution is Trick: Begin with high-resolution photos to preserve quality and sharpness in your layouts. Low-resolution images can lead to a pixelated final product.

Shade Matching: Pay attention to shade accuracy when creating for DTF printing. Use color monitoring tools to make sure that the colors in your style convert accurately onto the material.

Vector Videos: Utilize vector graphics anywhere feasible to maintain the high quality of your styles when scaling them to various sizes. (DTF Printing)

Test Prints: Constantly conduct test prints on example textiles to check the colors, resolution, and total design top quality prior to full-scale manufacturing.

Picking the Right Fabrics for DTF

When thinking about the optimum fabrics for DTF printing, the choice of material plays a crucial role in accomplishing the preferred top quality and resilience of the last published layouts. Selecting the best textile is important for making certain that the shades adhere well, the style stays lively and sharp, and the overall appearance meets assumptions. Fabrics with a high polyester material are normally preferred for DTF printing due to their ability to hold the ink well and produce dazzling prints. Polyester blends can likewise function effectively, providing a balance in between toughness and print top quality. Furthermore, fabrics with a smooth texture have a tendency to yield much better results as they provide a consistent surface area for printing, enabling specific outlining and color accuracy. It is necessary to consider the desired usage of the printed fabric when picking the product, as different fabrics supply differing levels of washability, breathability, and stretch. By carefully picking the ideal fabric for DTF printing, makers can improve the longevity and aesthetic effect of their designs.

Step-by-Step DTF Printing Process

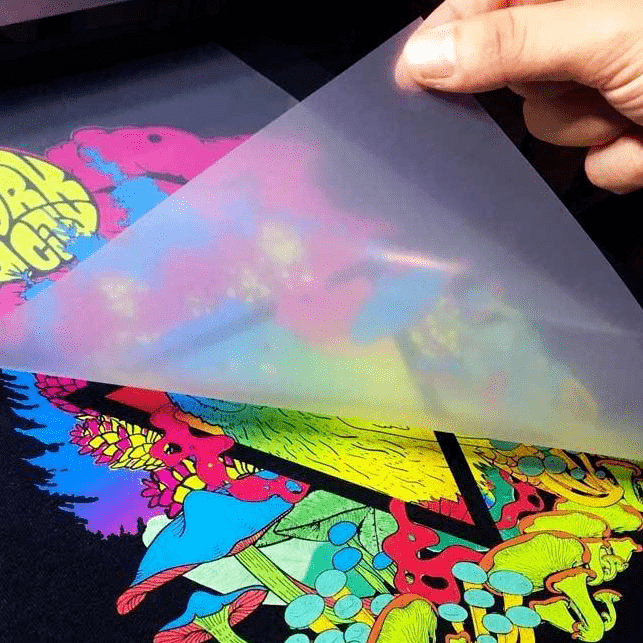

After treating, the printed design is then moved onto the textile making use of a heat press. As soon as the transfer is total, the material is allowed to cool down prior to the transfer movie is peeled off, leaving behind the long lasting and dynamic design on the textile.

Showcasing DTF Masterpieces

Have you ever before wondered at the elaborate information and dynamic colors of DTF masterpieces showcased on different fabrics? DTF printing has actually transformed the method layouts are moved onto fabrics, permitting exceptional precision and splendor in colors. When these DTF work of arts are put on display screen, they mesmerize audiences with their striking visuals and careful craftsmanship.

Among the most exciting aspects of showcasing DTF work of arts is the flexibility it offers. Whether it's a eye-catching and vibrant layout on a tee shirt, a thorough pattern on a pillowcase, or a personalized print on a canvas bag, DTF printing enables for countless possibilities. This adaptability enables artists and developers to release their creativity and bring their visions to life on a variety click this of fabrics.

Additionally, the durability of DTF prints ensures that these masterpieces can stand up to the test of time without losing their vibrancy. Whether shown in galleries, used as classy garments, or used as ornamental accents in homes, DTF work of YOURURL.com arts proceed to impress audiences with their extraordinary high quality and visual charm.

Conclusion

In final thought, DTF printing provides a flexible and ingenious approach for releasing imagination on different textiles. By checking out the advantages of DTF printing, developing with details pointers and methods, choosing appropriate materials, and following a detailed printing procedure, musicians can showcase their masterpieces effortlessly. This procedure enables the seamless transition from concept to creation, offering countless opportunities for creative expression.

In today's vibrant world of textile layout, the usage of Straight to Movie (DTF) printing modern technology has reinvented the process of moving detailed designs onto various fabrics.Creating efficiently with DTF printing includes understanding the ins and outs of electronic layout software application and comprehending exactly how to enhance designs for the finest outcomes on various textiles.When thinking about the ideal materials for DTF printing, the choice of material plays an essential function in attaining the preferred quality and sturdiness Visit Website of the final published styles. The following step is publishing the design onto an unique DTF transfer film utilizing a DTF printer with the suitable ink. By exploring the benefits of DTF printing, making with details ideas and methods, picking ideal textiles, and adhering to a detailed printing process, artists can showcase their work of arts with ease.

Report this page